Elastomer Granulation System

28/08/2020

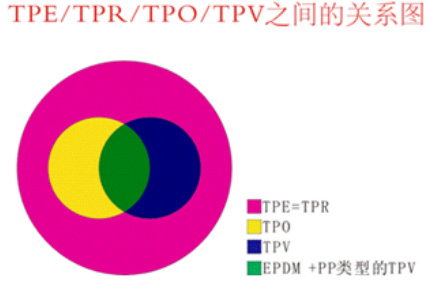

28/08/2020Thermoplastic elastomer (TPE for short) is a multifunctional material that exhibits rubber elasticity at room temperature and can be plasticized and molded at high temperature. It has both the elasticity of rubber and the melt fluidity and reusability of thermoplastics. It can not only replace general vulcanized rubber, but also replace some general-purpose resins, and can be extruded like plastics to keep its rubber elasticity unchanged. material. At present, thermoplastic elastomers mainly include styrene-based thermoplastic elastomers (SBC), polyolefin-based thermoplastic elastomers (TPO), polyurethane-based thermoplastic elastomers (TPU), copolyester-based thermoplastic elastomers (TPEE), and copolyamide-based thermoplastics Elastomer (TPA), polyvinyl chloride thermoplastic elastomer (PVC), etc.

The main application of parallel twin screws in the TPE industry is TPE blending modification and TPV dynamic vulcanization. TPE blending modification includes elastomer and plastic blending, filling, oil-extending, adding various functional additives to achieve specific hardness indicators, density indicators, fluidity indicators and various physical properties, and to meet some functional requirements. TPV, generally refers to PP/EPDM type dynamic vulcanized elastomer, English is Thermoplastic Dyamic Vulcanizate, and the word "dynamic" is added to more specifically explain that the process of producing this thermoplastic vulcanizate is dynamic vulcanization. This process refers to the rubber and In the process of thermoplastic melt blending, the rubber is vulcanized. While the rubber is vulcanized, it is continuously mixed with the thermoplastic. Therefore, the vulcanized rubber is distributed in the continuous phase of the thermoplastic as the dispersed phase.

There are two main process routes of TPE, namely, the mixer enters the twin screw after premixing and the weightlessness scale enters the twin screw for multi-channel measurement.

Photos missing here

Pre-mixed SBS formula

Photos missing here

Multiple loss-in-weight weighing systems needed for SBS production

There are also two main granulating methods for TPE, namely underwater pelletizing and strand pelletizing.

Underwater pelletizing production SBS

Flame-retardant TPE for cable production

There are two main process routes of TPV, namely, the weightlessness scale and the multi-channel metering respectively enter the twin screw and internal mixer for pre-mixing.