Masterbatch Granulation System

28/08/2020

28/08/2020There are many kinds of masterbatch in the plastics industry, such as filling masterbatch, color masterbatch, functional masterbatch, flame-retardant masterbatch, reinforced masterbatch, etc. The masterbatch mentioned here refers exclusively to color masterbatch and functional masterbatch.

Color masterbatch refers to the addition of a certain proportion of organic or inorganic toner to the carrier resin to make the toner uniformly dispersed into high-concentration colored particles. In general, the higher the toner concentration, the more difficult it is to make masterbatch. Color masterbatch is generally added with various organic pigments, the highest addition ratio is 40%; black masterbatch is generally added with pigment carbon black, the highest addition ratio is 55%; white masterbatch is generally added with titanium dioxide, the highest addition ratio is 75%.

Functional masterbatch refers to adding a certain proportion of functional additives such as antioxidants, stabilizers, ultraviolet absorbers, antistatic agents, slip agents, etc. to the carrier resin to make them uniformly dispersed into high-concentration particles. In general, the proportion of functional additives added is between 15% and 40%.

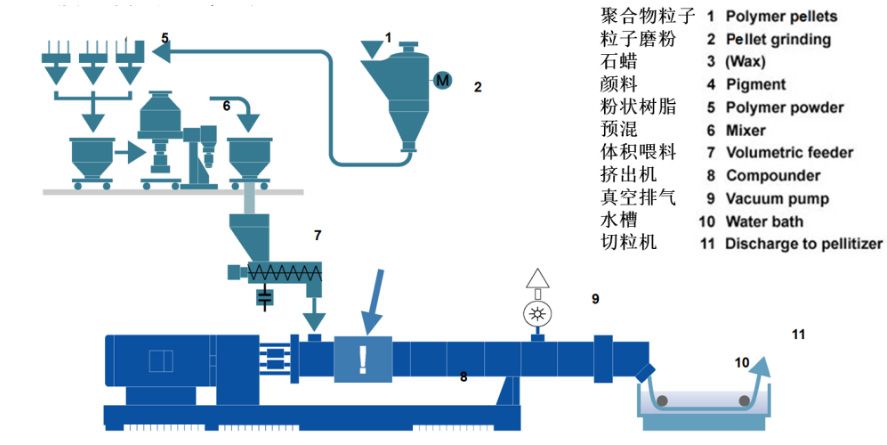

1. The production of masterbatch is divided into pre-mixing method and step-by-step feeding method according to the technological characteristics. The pre-mixing method is relatively simple. Generally, high-mixing machine is used for pre-mixing. The process flow is as follows:

Color masterbatch production process of pre-mixing method

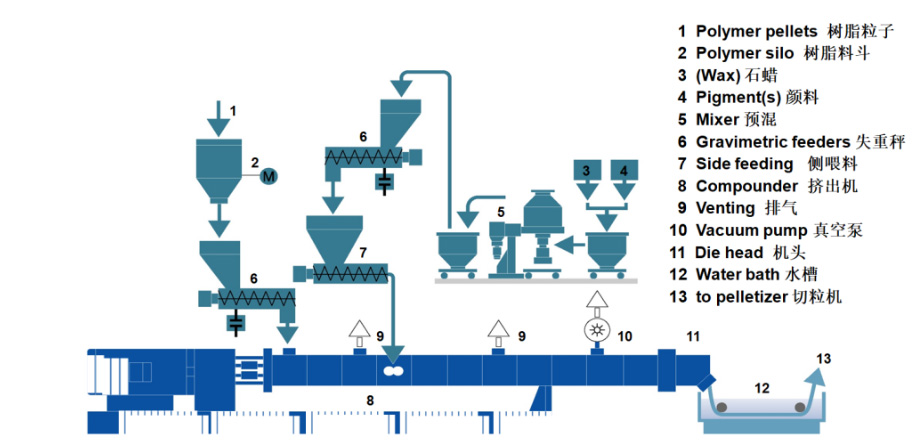

2. The step-by-step feeding method generally uses a weightlessness scale for accurate measurement. The production process is as follows:

Color masterbatch production process of multi-feeding method

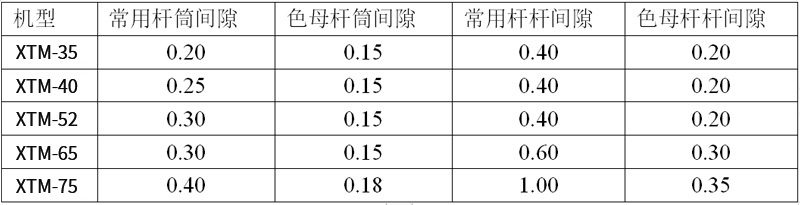

3. Xintuo equipment widely uses small gap design in the color masterbatch production industry to improve the shearing and dispersing ability and ensure product quality

4. White masterbatches and black masterbatches with high dispersibility requirements are generally premixed with internal mixers to improve quality

The production process of functional masterbatch is similar to that of color masterbatch, which can be used in one machine and take into account each other

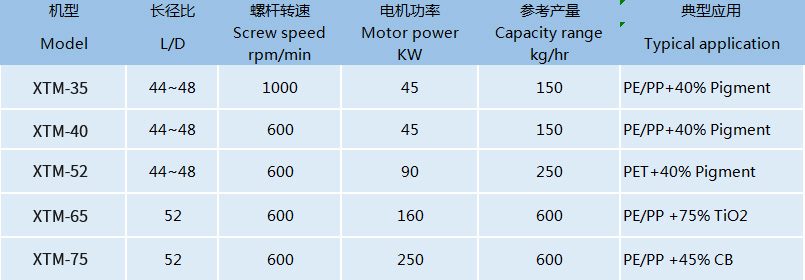

5. The typical host configuration is as follows