Engineering Plastic Granulation System

28/08/2020

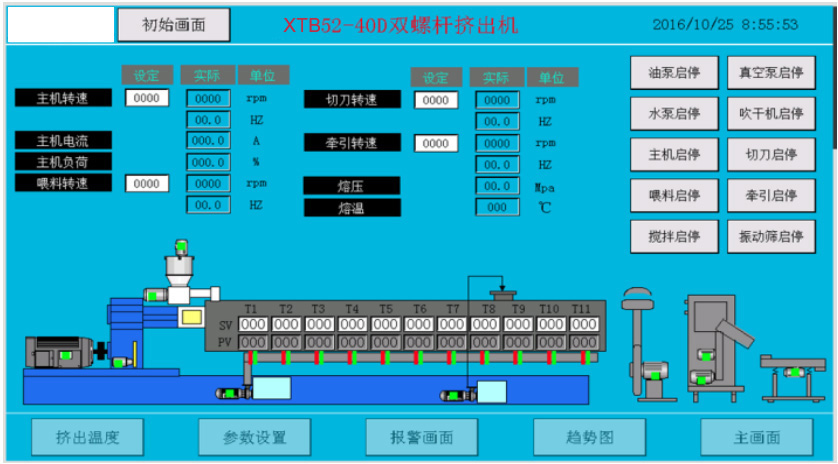

28/08/2020The modification of engineering plastics requires relatively high stability for twin-screw extruders, which is mainly reflected in the accuracy of the metering system, the transmission box can withstand high speed and high torque, the material of the barrel screw and the pelletizer have a long wear resistance, and the entire system Highly automated and digital

Automatic weighing system based on weightlessness scale measurement to meet the fluctuation error of each component raw material ≤0.5%

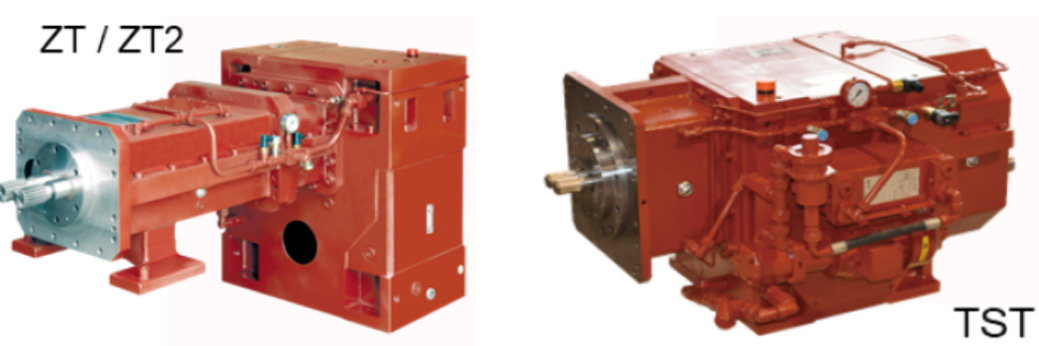

High-reliability gearbox, torque grade up to 13.5N.m/cm3, speed up to 1200rpm, transmission efficiency higher than 96%, safety factor ≥1.25

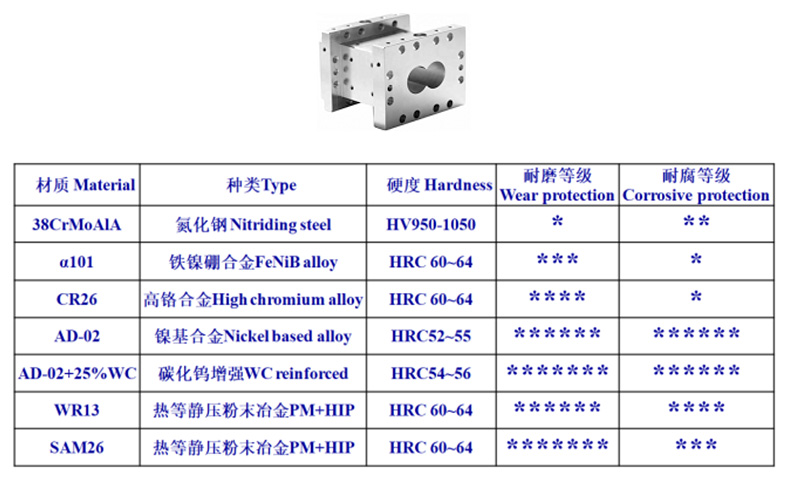

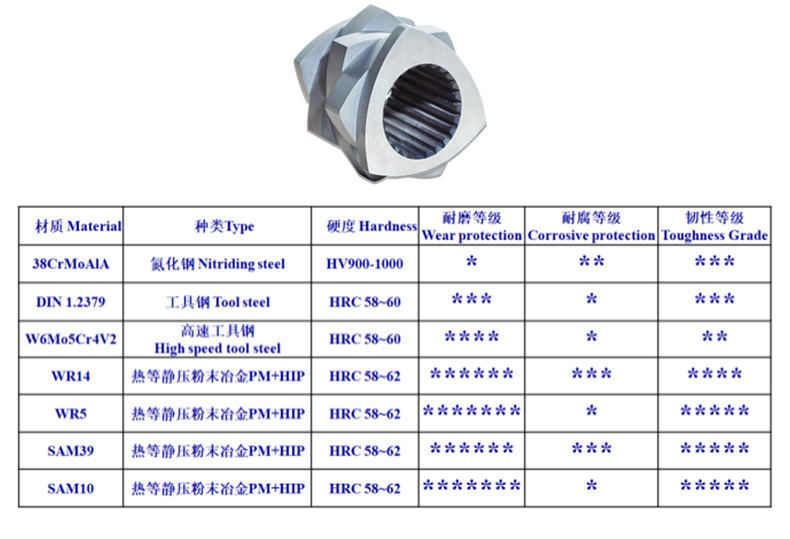

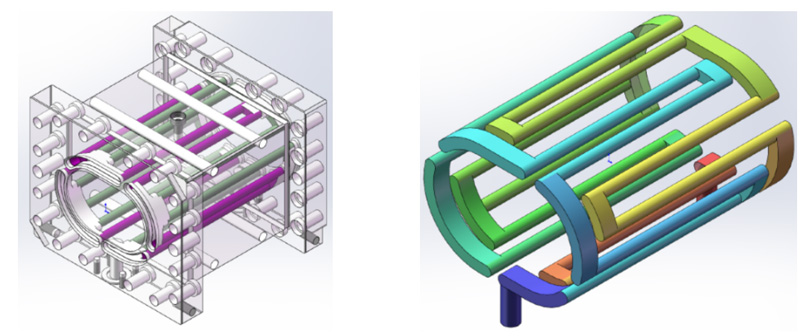

Provide a variety of barrel, screw, mandrel material solutions to meet the needs of customers at different levels

The typical cylinder material is as follows

Typical screw materials are as follows

Typical mandrel materials are as follows

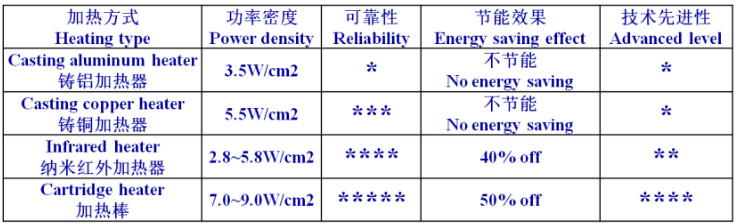

Provide a variety of barrel heating solutions to meet different energy-saving efficiency and stability requirements

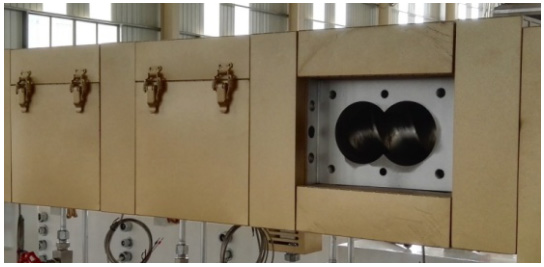

Cast copper and cast aluminum heating plate

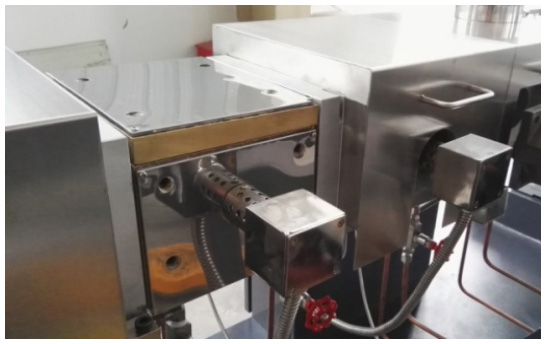

Nano infrared heater

Heating rod heating

Comparison of barrel heating methods

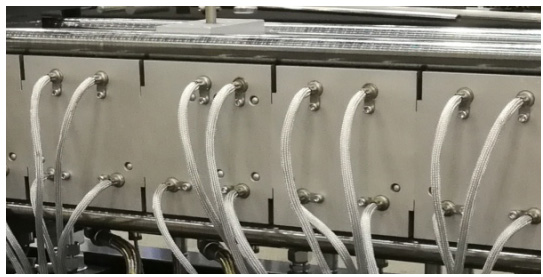

Provide an advanced double-layer composite water channel barrel cooling solution, which ensures efficient cooling while ensuring uniform temperature around the barrel

The cutter system of the pelletizer is made of imported materials, wear-resistant and durable, with sound insulation design, easy to clean

Based on PLC, IPC and the Internet, it can realize equipment automatic control integration, massive data storage, multi-device interconnection, and convenient various levels of management and remote debugging and diagnosis services

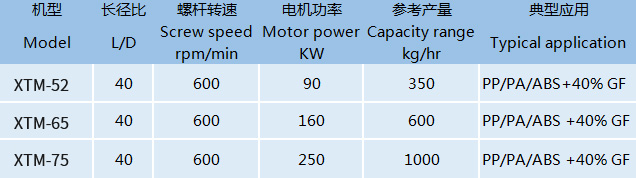

The typical host configuration is as follows