Categories

According to the state when the material is cut into particles, the cutting can be divided into two methods: cold cutting and die face hot cutting. Cold cutting means that the melt is first shaped and then cut. The melt is cooled and shaped by water cooling and air cooling; Hot cutting means that the melt is first cut into pellets on the die surface and then shaped. The molten material is cut into particles in the melt state. It is mainly divided into air-cooled die surface hot cutting, water ring die surface hot cutting, underwater die surface hot cutting and eccentric water The fog mold surface is eager.

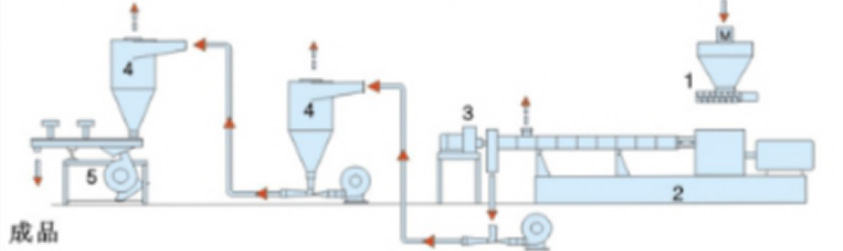

The eagerness of the air-cooled die surface means that the material is cut into particles and enters the air conveying system, where it is cooled and shaped in the pipeline or cyclone separator;

The water ring die surface eagerly means that the material is cut into particles in the air, and the melt particles are thrown into the water flow ring under the action of centrifugal force, and then enter the pipeline together with the water to cool and shape;

Underwater mold surface eagerly refers to the material being cut into particles in water, and directly following the water flow into the pipeline to cool and shape;

The eager cutting of the lower water mist die surface means that the material is extruded by the screw through the short runner to the large template, and then cut into particles by the eccentric chopper, and then cooled and shaped in the water mist environment.

The selection of the pelletizing system is mainly based on the technology, economy, degree of automation and other special requirements. Xintuo's standardized pelletizing methods include water-cooled strip cutting, air-cooled strip cutting, underwater strip cutting, air-cooled die surface eager cutting, water ring die surface eager cutting, underwater die surface eager cutting, and eccentric water mist die Noodles are eager.

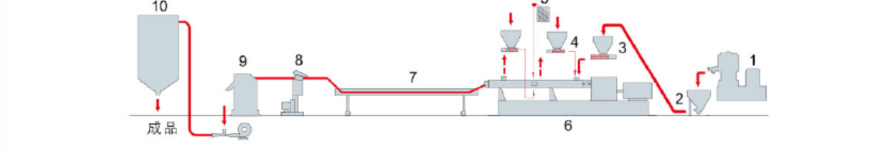

Water-cooled strips and diced

Air-cooled die surface eagerly

Water ring die surface eagerly

Underwater mold surface eager

Eccentric water mist mold surface eagerly