Categories

The formula can be pre-mixed to a certain extent before being added to the twin-screw extruder. The main purpose is to mix the formula uniformly and obtain certain technological goals, such as pre-plasticizing the resin and pre-absorption of additives. The difficult to disperse powder is pre-soaked, and the water-containing raw material is dried and dehydrated to a certain extent. Xintuo Machinery provides various mixing equipment and mixing solutions to meet the pre-mixing operations of different material systems.

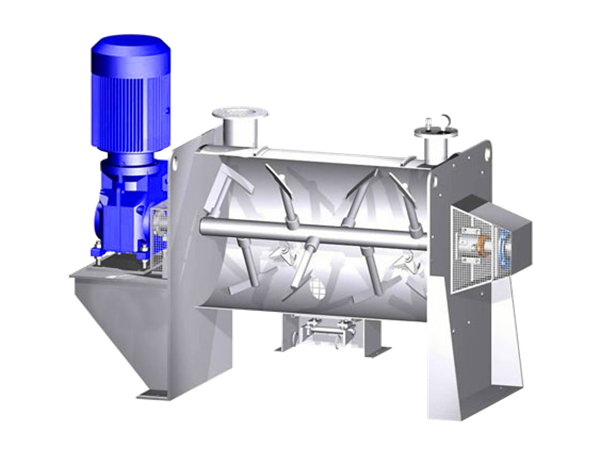

Horizontal ribbon mixer

It can perform simple cold mixing of materials, or add heating function to preheat and mix materials

High-speed mixer, also called hot mixer

The formula can be mixed with high efficiency at a very high speed. There are a variety of rotors to choose from to deal with different raw material systems. During the mixing process, the temperature of the materials increases through self-friction. The pot body is designed with a sandwich structure, and a medium can be added to heat or cool the pot body to achieve different technological purposes.

Low speed mixer, also called cold mixer

There are two types of structures, horizontal and vertical, and they are mainly used for the following purposes.

First: you can simply mix the materials;

Second: The jacket structure can be designed to cool the hot-mixed materials through water to reduce the degradation of the materials;

Third: The jacket structure can be designed, and the hot oil can heat the materials to melt the additives or dry the materials

High-speed/low-speed cold-heat hybrid unit, also called hot/cold hybrid unit

The combination can complete high-efficiency mixing of materials, and can also quickly cool down the hot materials after mixing to avoid damage to heat-sensitive materials. It is typically used in the mixing of heat-sensitive materials such as PVC, low-smoke and halogen-free.

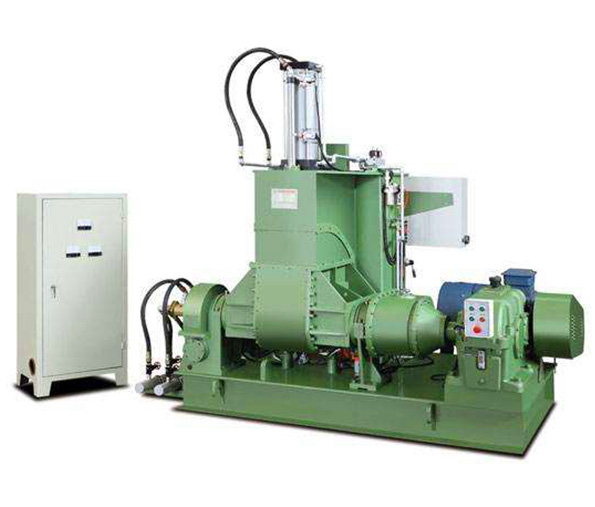

Internal mixer, also called kneader

The materials are deeply pre-mixed to reach the maturation level, especially for heat-sensitive and shear-sensitive materials, through effective pre-mixing, it is easier to achieve a high degree of dispersion effect, reducing subsequent equipment mixing requirements, and reducing the risk of material degradation.

Vertical mixing tank

Simple mixing and homogenization of the materials, and the auxiliary heating air can be used to simply dry and dehumidify the materials.